Sublimation printing is a great way to make t-shirts with sharp, lasting colors. However, it is traditionally used only on light-colored fabrics due to its unique method of transferring ink.

But did you know that it’s possible to sublimate even on dark-colored garments? If you’ve been wanting to learn how to print on black shirts or other dark fabrics, the secret is out!

The trick is to first attach a sheet of heat transfer vinyl (HTV) before printing. This creates an additional layer of protection so that when you sublimate, the ink will adhere to the HTV instead of directly onto the dark fabric.

Yes, can you sublimate on black shirts and other dark fabrics. The secret technique involves using heat transfer vinyl (HTV) first before sublimating on it. This creates a barrier between the fabric and the ink, preventing the ink from seeping into the shirt’s fibers and staining them. Here’s a step-by-step guide on how to use HTV and sublimation for dark shirts:

1. Design your image with a graphics software that can export in TIFF format. This will ensure that the colors remain vibrant when printed onto the shirt.

2. Cut out your desired design using an electronic cutting machine, such as a Cricut or Silhouette, in HTV.

3. Preheat your fabric for up to 3 minutes. This will ensure that the adhesion of the HTV is good and it won’t peel off after sublimation has been applied.

4. Place the pre-cut design on top of the fabric and press it on with a heat press machine, following the HTV manufacturer’s instructions.

5. Once the design is firmly pressed onto the garment, you can start sublimating! Sublimate your TIFF file according to your printer’s instructions, ensuring that the temperature and pressure are set according to the needs of the garment.

6. Allow the fabric to cool completely before peeling off the HTV transfer. If done correctly, you should be left with a vibrant and lasting design printed onto your dark fabric!

Read also: How long does sublimation ink last? Let’s find it out together!

Sublimation Printing Definition

Sublimation printing is the process of using heat and pressure to transfer dye onto certain surfaces such as fabrics, mugs, and other materials. Sublimation inks are specially formulated to turn from a solid form into a gas under the right temperature and pressure conditions.

Sublimation allows for vibrant colors, high-resolution graphics, and detailed images to be printed which makes it a popular choice for many printing applications. Sublimation inks do not print white and they are not visible when applied directly to dark-colored sublimation blanks or garments.

Sublimation cannot be performed on 100% cotton shirts due to the heat requirements of the process. Sublimation printing can be used to create custom designs on many different products, allowing you to create unique, personalized items.

Sublimation is a great choice for businesses looking to produce high-quality printed products.

Why sublimate on dark t-shirts?

Sublimation on dark t-shirts is a popular method for creating custom apparel designs with numerous colors. The process involves using a white, heat transfer vinyl (HTV) base layer and then sublimating the design onto the garment. This type of printing method is often chosen over heat transfer vinyl alone when there are many colors in the design.

This is because pressing multiple colors in heat transfer vinyl can be a tedious process, whereas sublimation onto HTV results in a much faster, cost-efficient printing method. Additionally, the colors are more vibrant and will last longer when using this technique on dark t-shirts.

When you need to create custom apparel with multiple colors, sublimation on dark t-shirts with a white HTV base layer is the best way to go.

Step-By-Step Guide on How to Sublimate on Dark T-Shirts

This guide will provide a step-by-step walkthrough on how to sublimate dark garments with the use of heat transfer vinyl and a cutting machine such as Silhouette Cameo or Cricut. This guide is suitable for those who wish to add additional flare to their light-colored shirts by using glitter or holographic as a base vinyl.

To begin with, you will need the following supplies: light-colored heat transfer vinyl of your choice (preferably Neon PU Heat Transfer Vinyl or Glitter White Heat Transfer Vinyl), a cutting machine (Silhouette Cameo or Cricut), scissors, weeding tool or pen, a heat press machine and sublimation heat transfer paper.

The next step is to create your design. You can do this by creating a vector file in Adobe Illustrator or CorelDRAW, or use a pre-existing ready-made design from your cutting machine’s library of designs.

Step 1: Cut the Vinyl

When cutting the vinyl for sublimation projects, it is essential to ensure both the vinyl and the sublimation transfer paper have the same size. This can be done using the software of the cutting machine. Before adjusting the size, consider what type of shape should be cut – square, round or custom-shaped according to the design.

If the design is more complex and has larger cavities, it is best to cut the vinyl in one whole piece. It is also important to use light-colored heat resistant materials for sublimation projects so that the colors of the transfer won’t be affected by the heat. Cut the vinyl accordingly and carefully to create a professional looking project!

Step 2: Print and Cut the Sublimation Paper

Are you looking to Print and Cut the Sublimation Paper for a project? It is a process that requires precision and attention to detail in order to achieve a successful result. First, you will need to open your cutting machine’s design studio and print the design on the sublimation paper, making sure that the vinyl and sublimation paper are the same size.

Print using the highest quality, slowest time for printing, and mirror the design in the printing preferences of your design software. Afterwards, set aside and let it dry for a couple of minutes. With scissors, cut out any excess material so that only your design remains on the sublimation paper.

Step 3: Heat Press the Vinyl First

Once the vinyl and sublimation transfer sheet is ready, it’s time to heat press it. Heat pressing the fabric is an easy process and the following steps should be taken to ensure a successful print:

Firstly, make sure that the design is correctly aligned to ensure a neat finish. Pre-pressing the fabric for 5 to 10 seconds before heat pressing is also important. It will help to remove any moisture from the fabric and ensure that the vinyl adheres correctly.

Then, set your Heat Press to the recommended time, temperature and pressure of the type of vinyl you are using. If you’re using PU HTV or glitter HTV, press at 266 °F to 284 ℉ within 8-12 seconds of pressing time. If you used other types of vinyl, be sure to check the Heat Press Temperature Guide for Vinyl before proceeding.

Once you have pressed the vinyl onto the fabric, allow it to cool completely before peeling off the transfer paper.

Step 4: Press the Sublimation Paper

Sublimating on dark garments can be a great way to add unique designs that stand out. To ensure you get the best results, it’s important to properly press the sublimation paper over the HTV. After pressing the HTV and letting it cool for a while, you should prepare to press the sublimation paper over the HTV. Place it correctly, and use thermal tape to keep it from moving when heat pressing.

For best results, do not use a mini heat press machine on the sublimation paper. Doing so may cause ghosting or scattering of the print, ruining your project. When ready to Press the Sublimation Paper, set your machine time and temperature to 190℃ for 50 seconds. With these easy steps, you can make sure your designs look great and stand out on dark garments!

Questions and answers:

What color shirts can you sublimate on?

Sublimation is a process in which a design or image is printed directly onto a garment, usually with the help of heat and pressure. This method of printing is particularly effective when it comes to creating bright, vivid colors and detailed designs on polyester fabric. While any color of shirt can undergo sublimation printing, white shirts are generally considered to be the best option due to their ability to absorb the inks and showcase the vividness of the design. While designs can be printed on light-colored shirts, white must not be used as a color within the image or else it will appear transparent.

What do I use to sublimate on black?

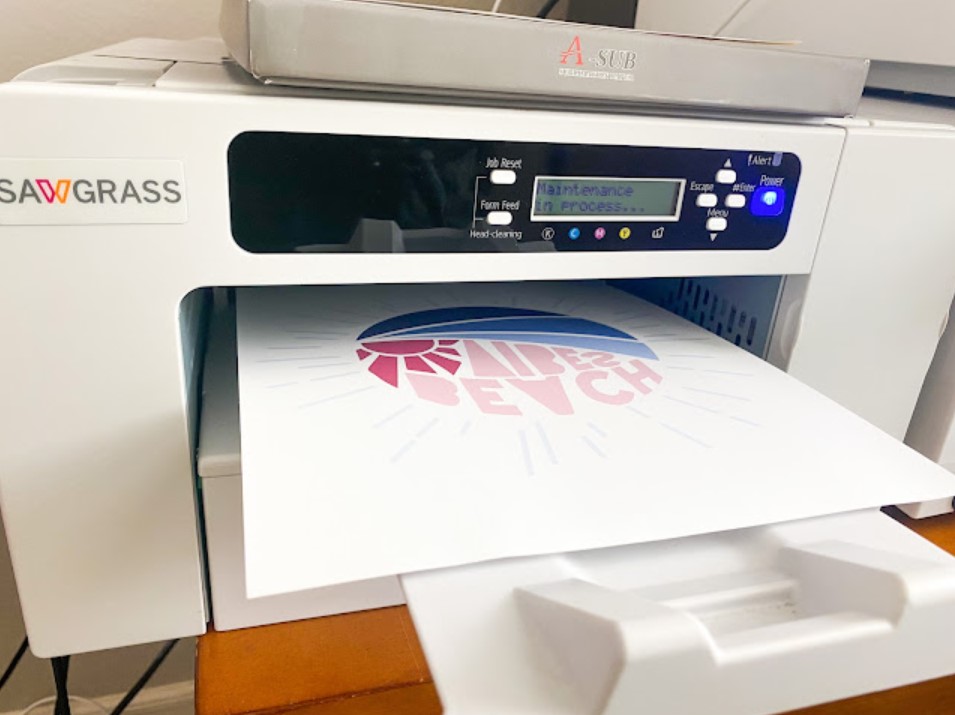

Sublimating dark colors can seem like a tricky task, but with the right tools and materials it’s totally doable. What you’ll need is a Silhouette CAMEO electronic cutting machine, a Sawgrass Sublimation Printer, and some white glitter heat transfer vinyl (HTV). With these three items in hand, you can create a look that’s almost as good as sublimation directly on dark colored fabrics.

Begin by cutting the desired design onto the white glitter HTV using your Silhouette CAMEO. Once you’ve finished, heat press the design onto your garment with a heat press.

Can you use sublimation on black shirts?

Yes, you can use sublimation to print designs on dark clothing items, including black shirts. To do this, a white heat transfer vinyl (HTV) is used as a base layer and the design is printed over it using sublimation ink. This process starts with pressing the HTV onto the shirt or other garment in the desired position and then sublimating the design over it. By using this method, you can create vibrant, lasting prints on dark clothing items without any drawbacks or limitations. So if you’re looking to add unique designs to your black t-shirts, hoodies, hats and more – sublimation printing is an excellent option!

How do you sublimate a dark shirt?

Sublimating a dark shirt is an ideal way to add bright and vibrant designs to garments. Sublimation printing involves printing onto special paper that transitions ink into a gas when heat is applied, before becoming a permanent part of the fabric. This process can be used for dark shirts, but it does require some extra steps. Read also…

Hi, I’m artist and sublimation printing expert. Born and raised in Anchorage, Alaska, I had passion for photography and painting from my childhood. I started my career as a sublimation print operator for a local printing company in 2012. The role exposed gave me lots of practical knowledge about printing process, from managing color profiles to ensuring print quality on various materials.

Leave a Reply